Popular Workshops

Our Virtual Team Building Workshops in Singapore are featured on:

EPIC Workshops - Leading Platform for Corporate Team Building Workshops in Singapore

Learn, Create & Bond

Exciting & Unforgettable Team Building

Great for Team Building, Get-Togethers & Events

There's always something for everyone!

Why You Choose Us?

Our Company Progress

At Epic Workshops, we pride ourselves as being one of Singapore’s leading platform for craft & hands-on activities.

These are some of the services we provide:

- Planning of Events, Live Workshops & Virtual Workshops

- Conduct of workshops for various events, celebrations and parties

- Supply of DIY Kits & Craft Materials

- Fringe Activities (booth-style, mini workshops) for your events

Plan disingenuous & innovative team bonding activities with Epic Workshops. Our dedicated event specialists will curate a specially designed program for your event for a unique experience.

500+ Positive Google Reviews

haidah2023-11-22easy to follow & fun! thankyou:)

haidah2023-11-22easy to follow & fun! thankyou:) Lovely Taidy2023-11-21Fun and informative experience with helpful instructors!

Lovely Taidy2023-11-21Fun and informative experience with helpful instructors! Simran Kaur2023-11-21Very knowledgeable and friendly staff with good and clear instructions 😊

Simran Kaur2023-11-21Very knowledgeable and friendly staff with good and clear instructions 😊 Syu Ahmad2023-11-17Had so much fun with the facilitators- they were so sweet and supportive! I highly recommend going for their classes 💕

Syu Ahmad2023-11-17Had so much fun with the facilitators- they were so sweet and supportive! I highly recommend going for their classes 💕 David Wong2023-11-16Staff is very helpful in assisting on the know hows.

David Wong2023-11-16Staff is very helpful in assisting on the know hows. PK Xie2023-11-16Colourful and happy experience

PK Xie2023-11-16Colourful and happy experience Swee Ai Emily Tow2023-11-14Great experience making a terrarium. Therapeutic and end product is something I like!

Swee Ai Emily Tow2023-11-14Great experience making a terrarium. Therapeutic and end product is something I like! Shi Hui Silia Puah2023-11-14Pleasant experience 🥰 instructions very clear and detailed. Cater to our pace

Shi Hui Silia Puah2023-11-14Pleasant experience 🥰 instructions very clear and detailed. Cater to our pace Dennis Lin Junxiang2023-11-14Clear and easy workshop to follow. Enjoyable!

Dennis Lin Junxiang2023-11-14Clear and easy workshop to follow. Enjoyable! Chee Mun Chan2023-11-11Had a super fun session with my daughter

Chee Mun Chan2023-11-11Had a super fun session with my daughter

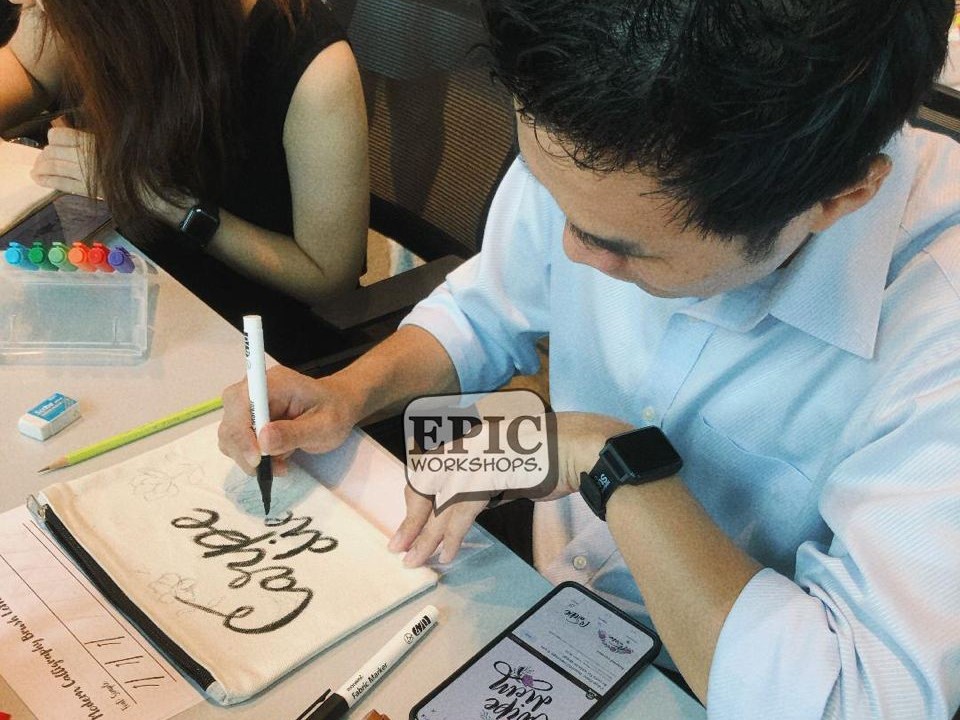

Workshop Gallery

View our past workshop experiences in the studio. Our workshops are suitable for the young & young at heart, so no matter which category you belong to or whatever your interests are, there’s always something in store for everyone!

Send us a message

For any inquiries on our Workshops In Singapore, kindly drop us an email at [email protected] / call (+65) 8150 8866 or simply fill in the form above. We’ll get back to you as soon as we can!

Contact us

- 37 #03-10 Jln Pemimpin, Mapex Building, Singapore 577177

-

Operating Hours - Monday - Saturday 8.30am - 6.30pm

Closed on Sundays

“At Epic workshops, we believe in the power of teamwork & Fun. That’s why we offer a range of unique & exciting workshops that bring teams together and help them achieve their goals. With over 4 years of experience, we’ve helped countless teams strengthen their bonds and reach new heights. Let us help your team to do the same!”

- 37 Jln Pemimpin, Mapex Building, #03-10, Singapore 577177

-

Monday - Friday

9 am - 6 pm

Closed on Saturdays and Sundays